Hospitals

A full-fledged MES for sterilization processes of surgical instruments

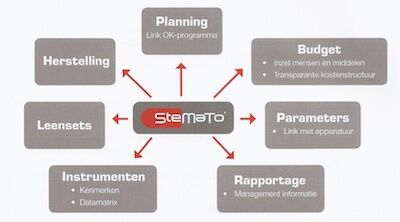

Based on Creonis’ standard MES framework, Creonis developed, together with BesCo BVBA, a management system for the sterilization of surgical instruments in hospitals (SteMaTo). The same principles of traceability and process monitoring as in an industrial MES indeed also apply here.

Traceability of instruments

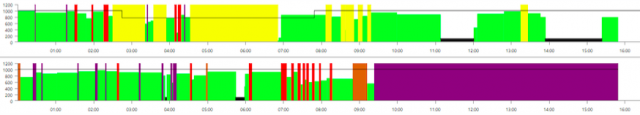

In the CSD (Cleaning and Sterilization Supply Department), all instruments needed in the operating room are cleaned, packed and sterilized. The system tracks the individually marked instruments both during cleaning and sterilization and from and to the operating rooms.

Integration and interfacing

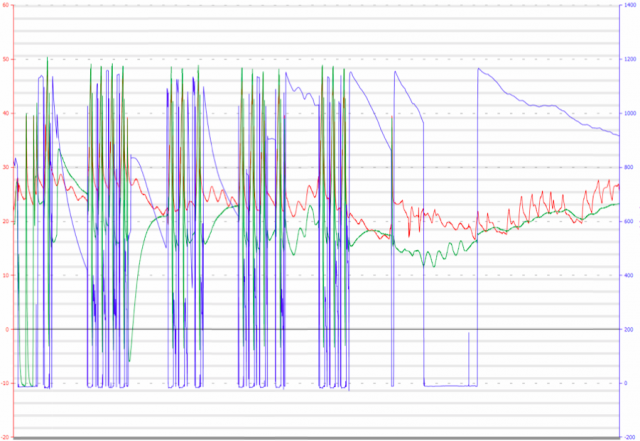

The planning of the operating rooms is incorporated in the system in real time. As a result, the CSD is informed which instruments are needed and with which priority. This guarantees that the right instruments are available at the right time.

In addition, there are interfaces with various equipment (washing machines, scanners, scales, sterilizers, etc.). An instrument set that does not have the correct sterilization profile (temperature and time) will not get the green light for use in an operating room.

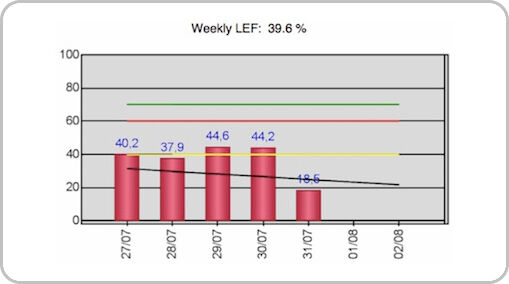

Management

Finally, a management module provides insight into turnaround and cost structure.

(Images: Besco BVBA)

Are you looking for a tailor-made solution? That’s possible!

In your company, too, we can help you smoothly monitor all operational process indicators.

Contact us for an informal chat, we’re happy to come and see you!

EN

EN  NL

NL  FR

FR